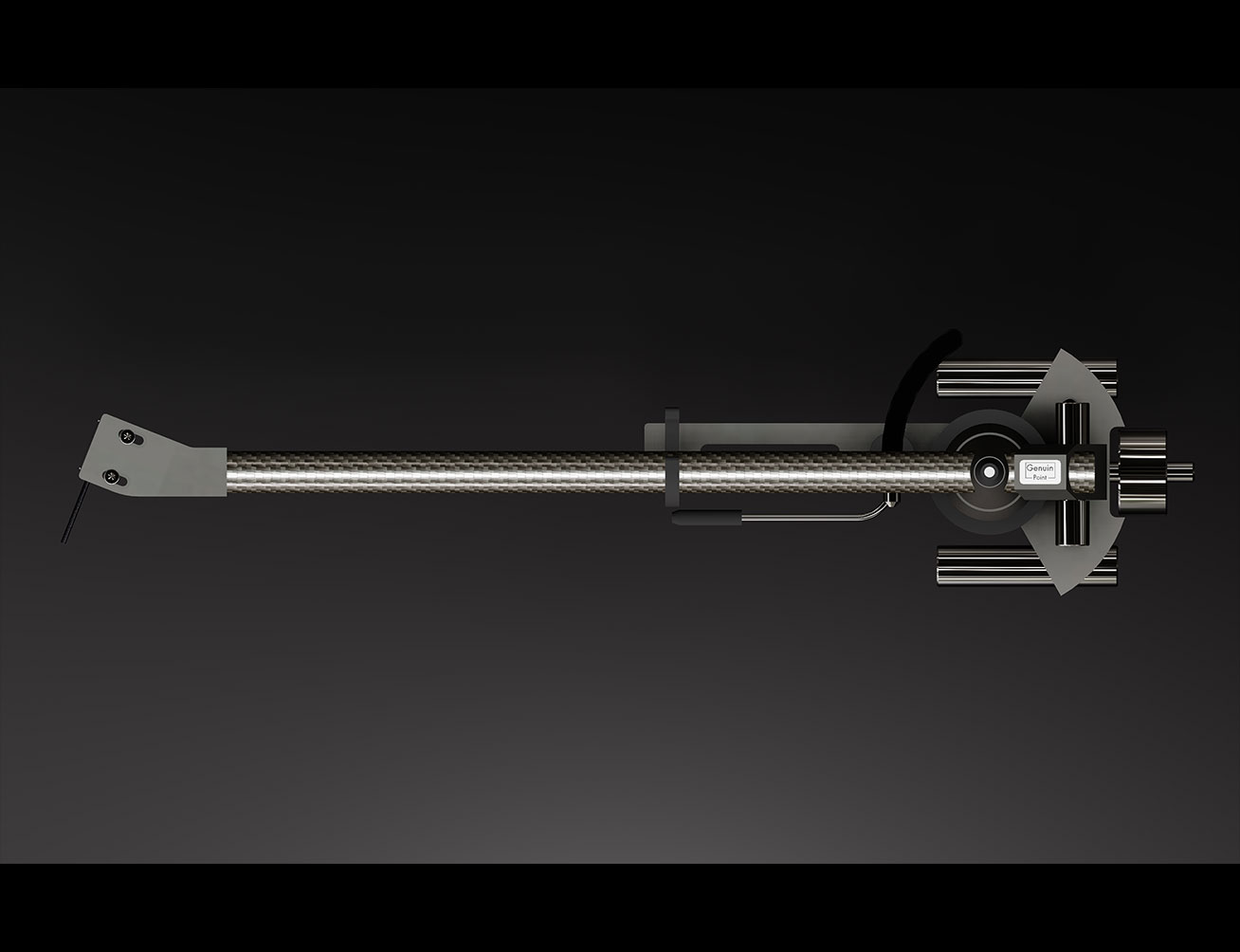

point The definitive unipivot tonearm

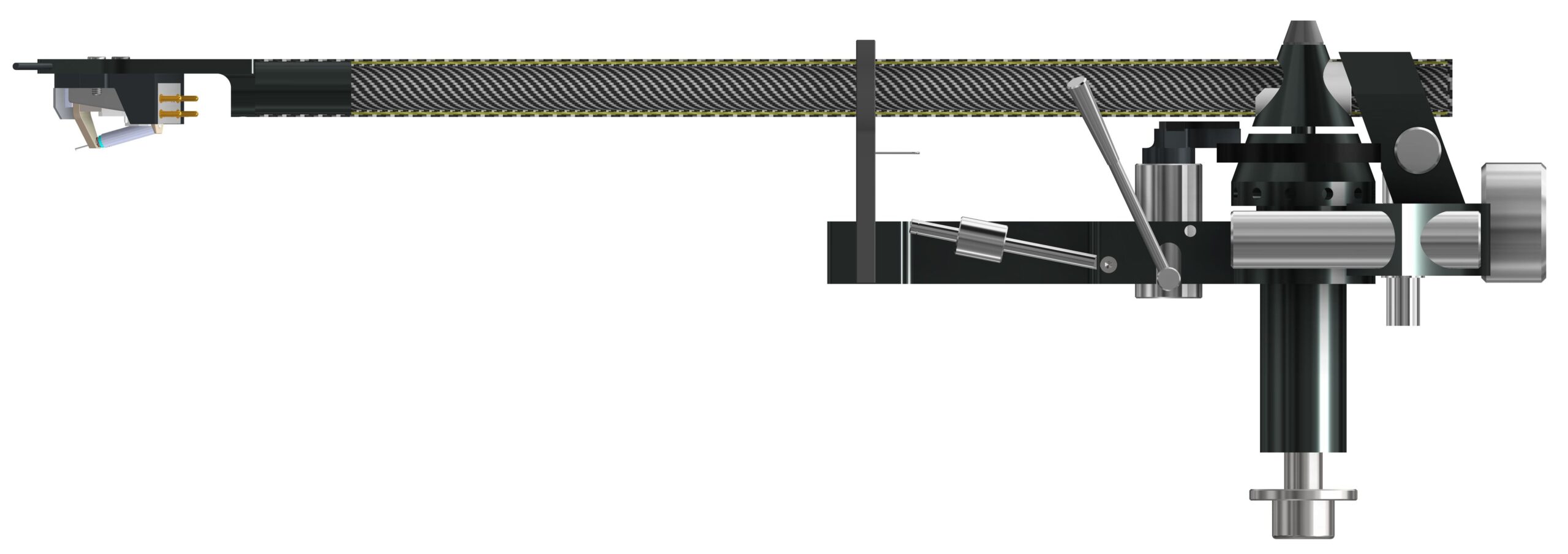

The genuin audio point tonearm transports the fragile signal coming from the cartridge absolutely neutrally and with maximum precision! The point literally “disappears” – as a potentially sound-influencing element in the analog playback chain. It serves exclusively as an intermediary between the cartridge and the phono preamplifier. The 10-inch tonearm developed exclusively for genuin audio is based on a reinterpretation of the proven unipivot design principle – but without the disadvantage of the typical, uncontrolled vertical tilt. Our point puts an end to this: it is the perfect unipivot tonearm!

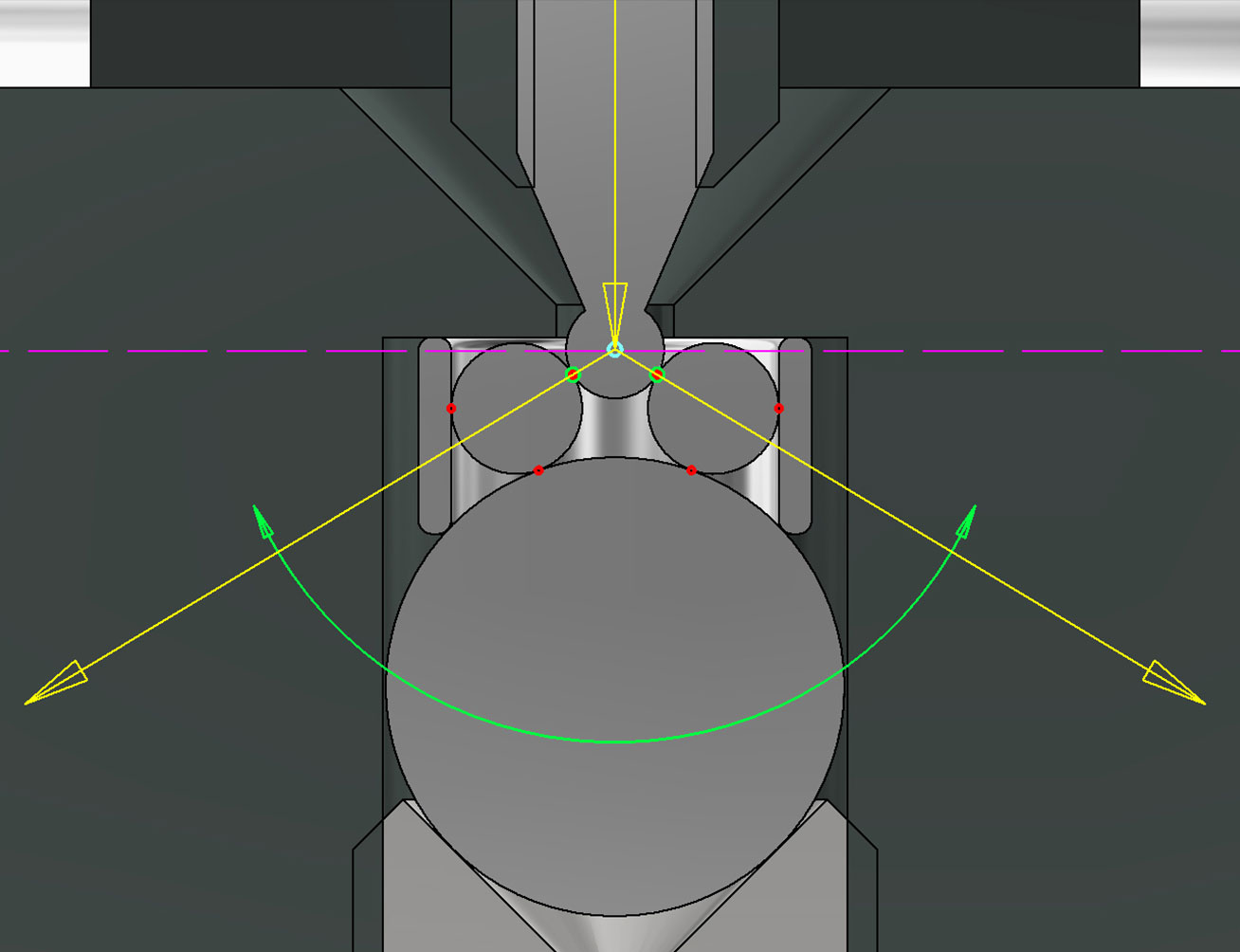

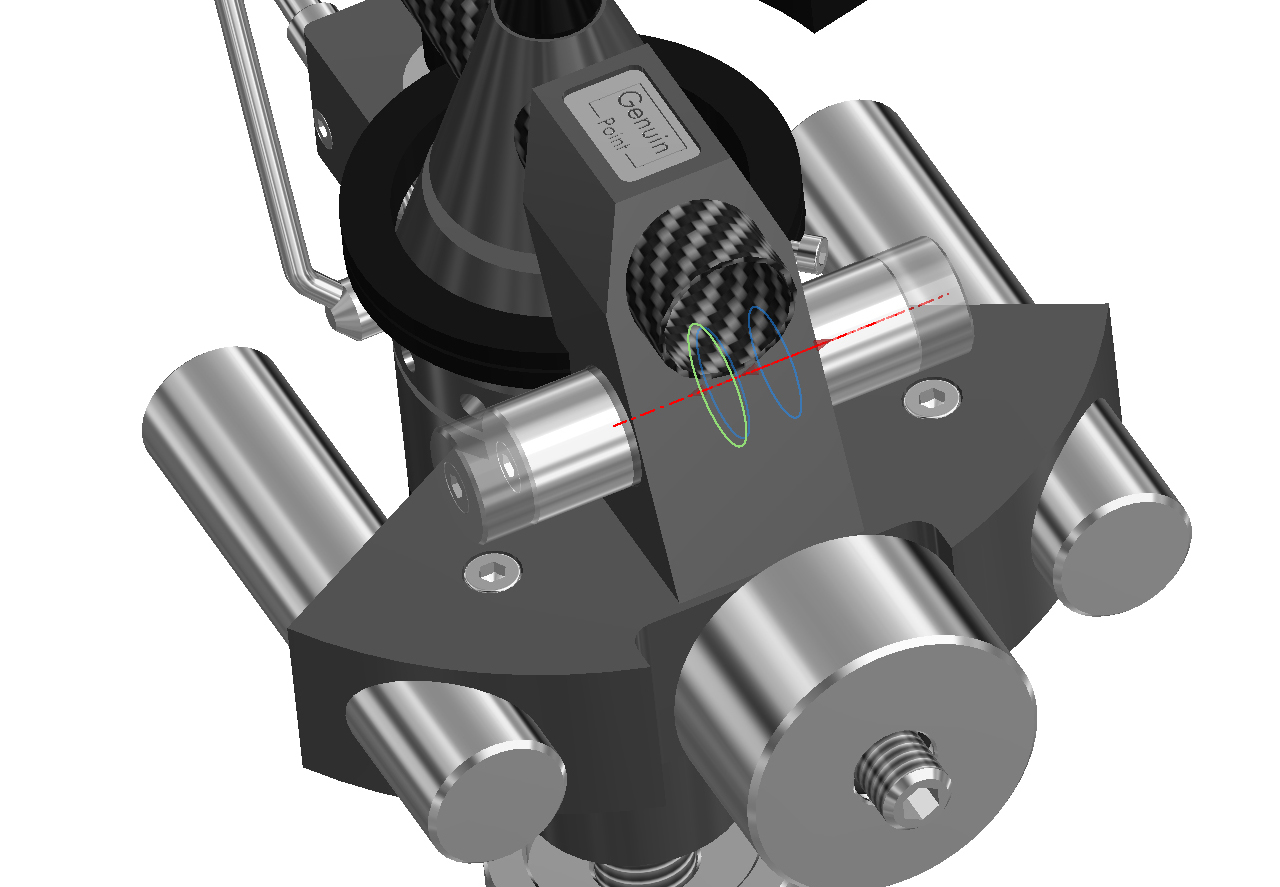

Unipivot bearing consequently thought-out

The unipivot bearing of the point is made up of various ball bearing elements. The geometry is designed for high-precision guidance in a horizontal plane and for exactly one fixed pivot point. The bearing tip consists of an adjusting screw with a welded and hardened bearing ball. The center of this ball forms the unchangeable pivot point, regardless of the position of the tonearm. The bearing is absolutely free of play and yet extremely damped – thus avoiding the feared “unipivot tilting”. Instead, it can achieve maximum mobility, flexibility and non-inertia during rotation. The excellent horizontal guidance results in an extremely clear spatial imaging.

Cut through the bearing center

The bearing tip consists of an adjusting screw with a welded and hardened bearing ball. Below that the figure shows the bearing design in the base top. This can be rotated for VTA adjustment and is guided by three O-rings. The tight fitting of the O-rings ensures a rigid connection to the lower part and therefore to the sub-chassis.

The horizontal azimuth adjustment is located on the zero level of the bearing, as are the anti-skating ring and the cartridge stylus.

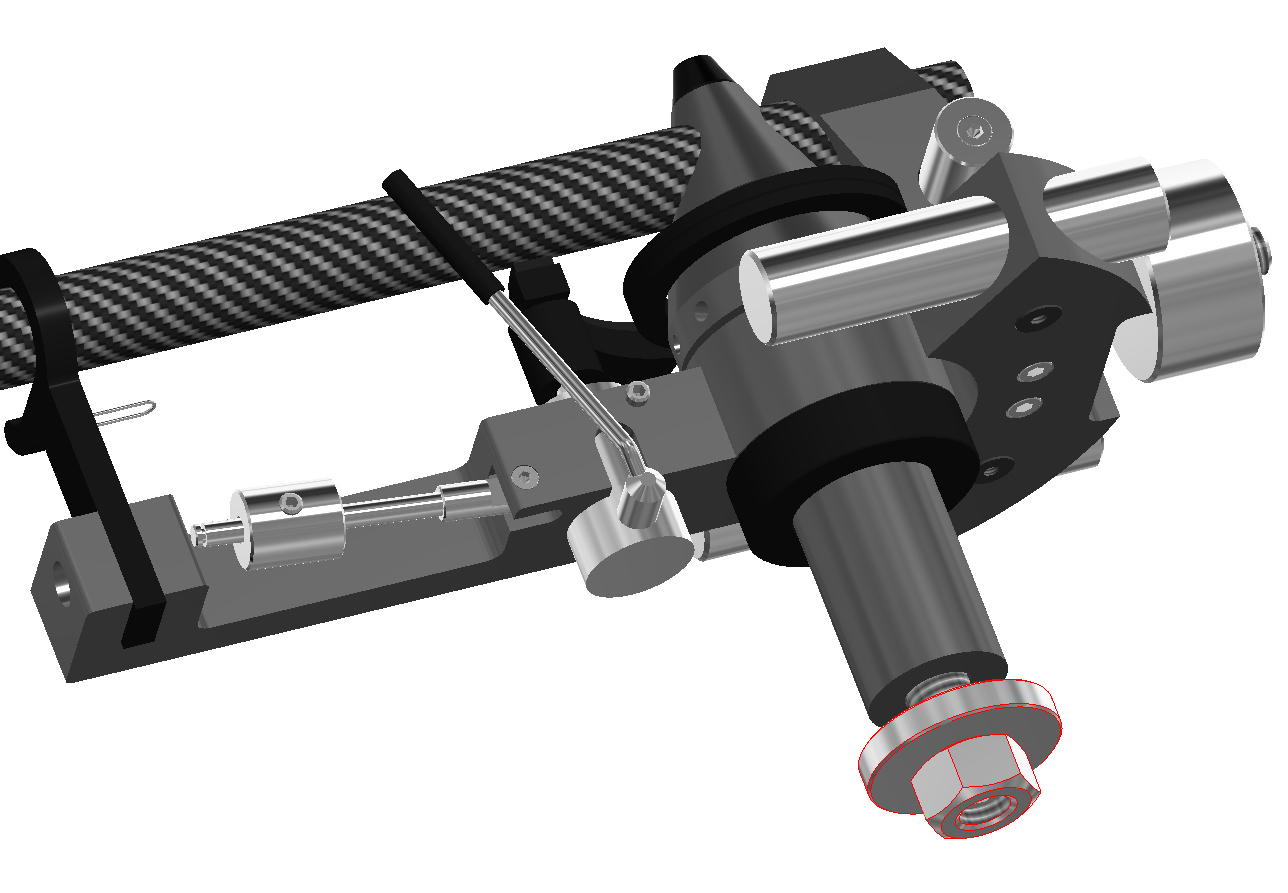

Substantive base

One of genuin audio’s core convictions is to avoid any form of sound-impairing influences. Turntables and tonearms are particularly susceptible to impact and reflected sound. To effectively counteract this, we rely on an extremely stable, low-resonance connection from the point to the turntable. The height-adjustable upper section of the tonearm is guided and damped via a particularly solid M8 thread and three O-rings and has two extremely low-built counterweights that can be moved to adapt to different cartridges. The basic setting of the tonearm is made with these counterweights while the exact adjustment of the tracking force is made via the central setting weight.

“point is the uncompromising evolution of a tonearm that I designed in 1978. All the knowledge acquired in the following years and in hundreds of projects has been consistently incorporated into the new point and ultimately makes this tonearm what it is now: a class of its own!”

Anti-skating on bearing level

The azimuth is set using an adjustable, transversely arranged weight. The anti-skating force is applied via a small weight attached to a thread – exactly in the plane of the unipivot bearing. This plane is also the plane of the tracking stylus diamond. Therefore, any forces applied when tracking the record have no momentum to twist the entire tonearm and thus also to change the tracking geometry.

Carbon und aluminum

The genuin audio point is made of carbon – a material that ideally combines lightness and stability. The point‘s headshell, on the other hand, which is bonded to the thin-walled tonearm tube, is made of aluminum. The relatively high weight of the headshell further contributes to the rigidity and ensures maximum mass inertia in the area of the cartridge. We also emphasize this here: Unwanted signal interference from resonances of any kind must be avoided! This “must” is also consistently implemented inside the tonearm.

“…a tonearm that provides best tracking with a variety of cartridges…”

Eliminating vibrations

The carbon tonearm tube is also bonded over a large area – both to the carrier for the counterweights and the mount for the single-point bearing tip. A concentrically arranged inner tube – also made of carbon – in combination with a damping gel specially developed for the point, which fills the cavity between the two tubes, effectively puts an end to low- and high-frequency vibrations.

The tonearm design consists of two concentrically arranged carbon fiber tubes. The space in between is filled with a special two-component gel to effectively dampen resonances in the tonearm tube.

Multiple damping

The internal carbon tube is connected relatively rigidly to the headshell at the front via an O-ring. At the other end, directly in the area of the tonearm pivot point, it is glued to a free-swinging inner weight. This design makes sure that the low-frequency vibration energy is largely absorbed by the outer tube.

Higher-frequency vibrations with lower amplitudes are “swallowed” by the damping gel. This unique construction, which has been thought through down to the smallest detail, contributes only insignificantly to the moving mass of the tonearm.

Even the heavy internal weight has very little influence on it, as it is so close to the pivot point. The multiple, elaborate damping measures ensure that the point can play free of any sound coloration.

Continuous wiring

In order to drastically minimize the number of soldering points and the associated signal interruptions caused by eddy currents, the point is wired through – using a special cable made of high-purity silver. The tonearm cable leads from the connection pins of the headshell directly and without interruption to the connector plug for the genuin audio drive turntable. genuin audio uses high-quality products from the LEMO brand for both the point‘s connector plug and the drive’s matching input socket. Of course, the point can be individually configured for your turntable in terms of tonearm base and connections.

Quick exchange

The tonearm base makes it possible to use several point tonearms – ideal for operating different cartridges. Once the cartridge has been adjusted, the point can be kept preset and replaced in a few simple steps. Only the anti-skating thread needs to be attached. Thanks to its extremely user-friendly height adjustment, the VTA can be set correctly within minutes.

Technical specifications

| Design | Unipivot |

|---|---|

| Geometry | 10″ Baerwald/Löfgren |

| Effective Length | 254 mm (10″) |

| Overhang | 16.2 mm |

| Offset Angle | 21.6° |

| Special Features |

|

Press comments on the genuin point

“A perfect single-point tonearm that purposely eliminates the pitfalls of this principle. … For a uni-pivot tonearm, the imaging precision and the clear focus of the point are probably unique. … Regardless of the price tag, the thoughtfully designed and easy-to-use tonearm presents itself on a par with some of the finest exponents of its kind.”

Helmut Hack in Fidelity Magazine, Ausgabe 01/2018

Download Review